The time is ripe for large-scale carbon capture, usage and storage (CCUS), a suite of technologies that trap carbon dioxide produced by industries and fossil-fuel power plants, then bury it underground or recycle it. The Intergovernmental Panel on Climate Change (IPCC), in its 2018 Special Report on Global Warming of 1.5C , found that ‘all pathways to limit global warming to below a 1.5C rise in median global temperatures forecast the use of Carbon Dioxide Removal (CDR) of about 100–1000 gigatonnes of CO2 this century. That’s equivalent to removing about 6 billion blue whales of CO2.

—

What Is Carbon Capture?

Carbon capture technologies have been around since the 1970s but have been in limited use. There are 17 large-scale plants in the world, mostly in the US, that put away about 40 million metric tons of carbon dioxide – roughly 1% of global annual emissions.

The technology is gaining momentum. The UK Government and International Energy Agency (IEA) held a pivotal summit to kick-start carbon capture projects in November 2018, bringing together 50 international leaders, CEOs of major energy, manufacturing and finance firms.

Claire Perry, Minister of State for Energy and Clean Growth, pledged £20 million (about US$24 million) to construct carbon capture technologies at industrial sites across the UK, as part of £45 million (about US$54 million) commitment to innovation, and will invest £315 million in decarbonising industrial sites.

Britain is forecasting large-scale carbon capture by mid-2020s, said the UK Department for Business, Energy and Industrial Strategy (BEIS).

Norway is also looking to build Europe’s largest carbon-capture project. The Ministry for Petroleum and Energy revived plans to develop CCS technology with a pledge of €30 million (about US$32.1 million) in May 2018.

These developments could lay the groundwork for an Europe-wide boom in carbon capture, which will require significant capital investments to bring costs down.

A Carbon Capture and Storage (CCS) testing facility in Norway. Image: Technology Centre Mongstad.

If you want to learn more, check out this next: What is Carbon Capture Technology?

How Does Carbon Capture Work?

A carbon capture project consists of five phases: generating CO2, capturing the emissions (a two-part process), transporting it with trucks, and injecting it deep underground and then monitoring it.

Capturing CO2 is most effective at combustion sources, such as at large fossil fuel plants and industries with major CO2 emissions. Extracting CO2 from the air – Direct Air Capture (DAC) – is possible, but its lower concentrations in the air poses significant engineering challenges.

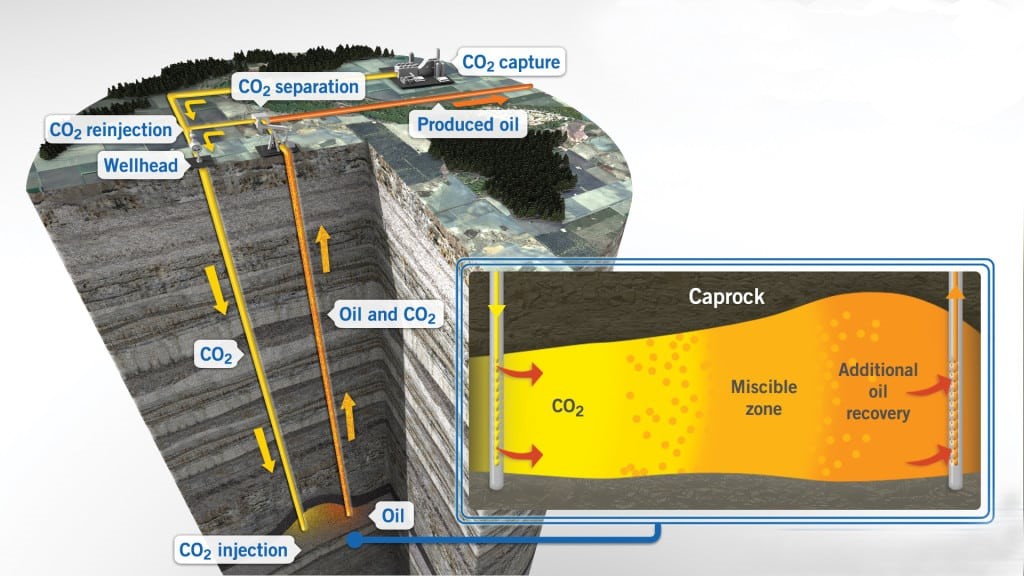

Carbon dioxide can also be utilised in a process known as “enhanced oil recovery” (EOR) – injecting CO2 in depleted oil fields to produce incremental barrels of oil. Enhanced oil recovery is not a new process and has been in commercial use for the last 40 years.

Enhanced Oil Recovery: CO2 is injected underground into mostly depleted oil reservoirs, dissolves trapped oil and brings it to the surface. The CO2 that rises with the oil (about half stays underground) is captured and reused. Image: 2016 Global CCS Institute.

The US Department of Energy said in a statement, “While we’re safely and permanently storing large quantities of CO2 underground, we’re also working on beneficial CO2 utilisation. Enhanced oil recovery is one important pathway.”

Though some CO2 resurfaces with the oil, it is captured, separated, and pumped right back into the oil reservoir. In practice, around 90 – 95% of the CO2 used in enhanced oil recovery ends up underground, which is why the industry needs a steady supply of CO2 – to continue recovering oil through EOR.

Beyond utilising carbon for EOR, researchers are looking to convert CO2 in to products, which some foresee as a trillion-dollar market that will capture billions of tons of CO2.

A Canadian startup has converted CO2 into nanoparticles used for concrete. Researchers in Bangalore, India aim to convert CO2 into methanol, used to make resins, pharmaceuticals, perfumes and more. Meanwhile, a California-based startup is capturing CO2 for the production of bioplastics, in a collaboration with the furniture giant IKEA.

Many of these innovations are still in the early stages of development.

You might also like: Tropical Forests Are Losing Their Ability to Store Carbon

Reframing Carbon As An “Asset” and Driver of Economic Growth

In the report Making Carbon a Commodity, the authors suggest that carbon is an economic commodity that could add $190 billion to US GDP by 2040 and create 780, 000 jobs through enhanced oil recovery.

89 billion barrels of additional oil are trapped in onshore reservoirs, the US Department of Energy estimates – in stark contrast to the country’s current proven domestic reserves of 21.9 billion barrels.

Enhanced oil recovery methods can tap in to this production, according to the Department, increasing the country’s oil recovery from approximately 30% to 60%.

Carbon capture can be an attractive option for developing countries that face conflicting priorities in balancing energy needs and emissions reductions.

China is the perfect testing ground for large-scale deployment of carbon capture technology, experts say. The country is developing their own CCUS technology and has 9 carbon-capture projects in pilot stage.

As the world’s top energy consumer and CO2 emitter accounting for 30% of global emissions, China not only needs carbon capture, but is well-equipped to implement its mass-scale deployment with heavy-handed governments and state-owned enterprises.

Sinopec, one of China’s largest oil and gas companies, uses enhanced oil recovery on Shengli oilfield, located in the Yellow River delta in Shandong province. Shengli is the second-largest oilfield in China and became depleted after peak production in the 1990s.

By capturing CO2 and pumping it in the ground, Sinopec is now increasing the field’s yield, while recovering CO2 from the atmosphere.

In the absence other financial incentives to cut emissions, enhanced oil recovery is a selling point for carbon capture technology. EOR can be effective pathway for China and other developing nations to maximise their own oil production capacity.

Unlocking Funding Opportunities for Carbon Capture Technology

While carbon capture is technologically feasible, it has a Catch-22 type of funding problem.

Without incentives to cut emissions in the form of a tax credits or carbon dividends, banks are less likely to appraise a CCUS project as economically feasible. Yet if the costs of carbon capture were lower, its mass deployment could be profitable.

CURC and Clearpath Foundation advocate for the increase in use of public-private partnerships (PPPs) to develop and scale up early-stage carbon capture technologies, addressing the major challenge of carbon capture: the large capital investment required.

The US Department of Energy could play a crucial role in funding PPPs, as it did in the case of the Petra Nova plant in Texas, the first and only carbon-capture unit in the US installed on a coal-fired power plant. The Department oversees federal efforts to advance the deployment of CCUS technology and is an important proponent of carbon capture R&D and financing.

Shifting the public’ awareness of CCUS is also important for its roll-out. “CCS doesn’t make anything new… People don’t tend to see it as something additive; they tend to see it as something subtractive.”, says CCS expert Julio Friedmann. “That’s why people tend to look at it as a cost, as opposed to an investment. That needs to change.”

You might also like: 3 Carbon Capture Technologies We Must Scale Up to Meet Net Zero