Among the most pressing environmental issues that need to be addressed are food production and food waste. Thankfully, we now have a multitude of sustainable technologies that can help us grow food without destroying our planet. One of them is insect farming. Founded in 2019, the agri-tech start-up FlyFarm has positioned itself as a leader in this rapidly growing market, growing black soldier fly larvae on organic waste to reduce emissions and produce sustainable protein feed.

—

The Protein Crisis

Driven by the relentless human population growth – the global demand for proteins is set to increase by about 60% by 2050. Besides this exponential increase, what is truly concerning is the fact that current protein production utilises extremely unsustainable methods. Traditional farming systems put tremendous pressure on our environment, contributing to the depletion of already stressed wild fish stocks and water sources.

To meet the need for protein to sustain a global population of 10 billion people by 2050 sustainably, new farming methods are required. But what’s the best solution? An increasing number of experts would answer this question with two words: insect farming.

Insect Farming: All You Need to Know

Insects are incredibly easy to raise due to their fast reproduction rates and they are also incredibly high in protein. Believe it or not, insects such as mealworms, crickets, and black soldier fly larvae have been shown to provide significantly more protein than meat.

Perhaps the biggest benefit of producing edible insects for human and animal consumption is that they can be raised on food waste. Modern insect farms can produce low-cost protein by upcycling organic waste. It doesn’t stop here. When coupled with renewable energy, the production process also has a significantly lower carbon footprint. Research suggests processing waste through insect bioconversion generates up to 90% less greenhouse gases compared to landfill or composting. Additionally, insect farming saves about 100 times the CO2 emissions and requires between 50% and 90% less land in comparison to conventional livestock, freeing up space for the cultivation of foods for human consumption.

Given the multitude of benefits, it comes as no surprise that the insect protein market is growing extremely rapidly and is expected to be worth US$10 billion by 2030. According to data from Dealroom.co over 400 companies worldwide have so far taken up the challenge of producing protein feed from insects and the number is set to grow very rapidly in the coming years. One of them is FlyFarm. Striving to develop insect farms as a means of producing animal feed, the agri-tech company headquartered in Singapore hopes to address some of the food chain’s most pressing issues. We sat down with Constant Tedder, FlyFarm’s Founder and CEO, to discuss how black soldier fly larvae are grown for pet as well as poultry and fish feed.

You might also like: Entomophagy: An Easy-To-Digest Solution to Save the Planet

How FlyFarm Is Shaping the Insect Farming Sector

Founded in 2019 by serial entrepreneur and passionate sustianability advocate Constant Tedder and Andres Crabbe, FlyFarm Worldwide Ltd., the agritech start-up builds black soldier fly larvae biorefineries which bioconvert organic waste to reduce emissions and produce sustainable protein for pet and animal feed.

The company has successfully raised in excess of US$5 million in two seed rounds to develop their highly automated first cloud-connected pilot farm in Brisbane, Australia, where the livestock industry contributes about AU$31 billion (US$22 billion) to the national economy annually.

“Our vision is for a world where pets, farmed fish and poultry are fed with sustainable protein from insects reared on organic waste,” explains Tedder.

Since its inception, FlyFarm has been working with several waste partners to secure different types of organic food waste to feed their black soldier fly larvae, including on-farm waste, waste from the agribusiness and food preparation, unsold food from retailers as well as food and beverage manufacturing waste.

FlyFarm’s insect choice is not coincidental. Black soldier fly larvae have enormous potential. These wide ranging insects are super converters of organic waste with an incredibly high growth rate. Not only can they eat 50 times their body weight in basically any type of food waste but female flies can also deposit between 200 and 600 eggs a day which hatch after about four days, making them an extremely prolific species. Moreover, black soldier fly larvae are very rich in protein and amino acids, which makes them an excellent food source for pets, poultry, and fish.

Headquartered in Singapore, Tedder and Crabbe work with a team of passionate and skilled engineers and biologists located in Brisbane – where they operate a demonstration plant that proves their subsidiary FlyFarm Systems insect farming robotics and automation technology – and are now looking to expand the business in Australia. The company has recently embarked on an innovative collaborative joint research partnership with James Cook University (JCU) with the intent to better understand and advance Black Soldier Fly (BSF) larvae production at industrial scales.

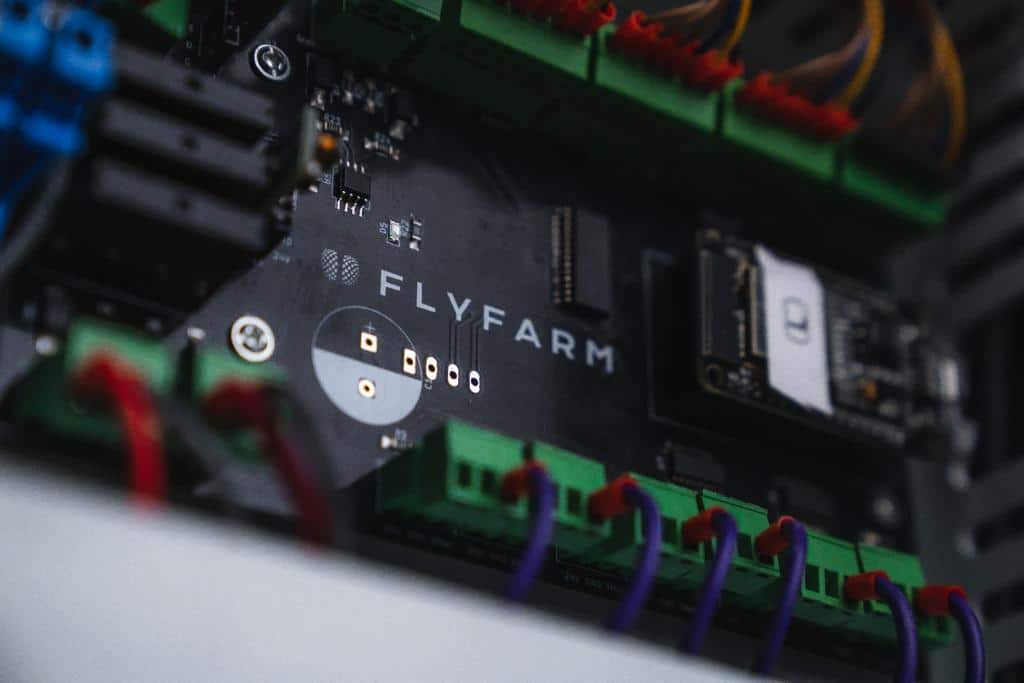

FlyFarm Systems builds robotics and software to automate the farming process. Image: FlyFarm.

By striving to tackle the joint problems of emissions from waste and the sustainability of protein supply chains – FlyFarm is addressing some of the most pressing environmental issues while generating high-value products, abating GHG emissions from waste and promoting a circular economy:

“The problems we are addressing are organic waste and the emissions and costs that it generates – as well as the unsustainable supply of protein for growing pet food and aqua feed markets.” – explains Tedder.

“Our ambition is to build the world’s largest network of highly automated insect farms – operating on our scalable technology platform producing traceable sustainable protein for large commercial buyers seeking to improve their Scope 1 and 2 emissions. In 10 years we can have a network of FlyFarms in every continent.”

Final Thoughts

Insect production on a large scale requires a fraction of the land, water, or energy, as other ways of producing farmed protein. BSFL and many other farmed insect species can be fed using organic food waste or bi-products from agricultural, food processing, or manufacturing processes. In addition to lowering emissions and generating value from waste – the product insect protein meal itself displaces unsustainable sources of protein still widely used such as fishmeal made from pelagic or ocean caught fish.

Earth.Org believes that there is a gargantuan opportunity to recycle organic waste and believes companies like FlyFarm are showing that insect bioconversion eliminates emissions at the same time produces high-value sustainable protein.

Challenges remain for post-consumer waste around waste segregation and incentives for consumers to ensure their waste is free of contaminants. Governments should focus on ensuring that organic waste can be recycled.

You might also like: 11 Effective Solutions for Food Waste